My role:

-Industrial Designer

-Fabrication Specialist

-Sustainability Researcher

-Accessibility Designer

-Packaging/Systems

Designer

Objectives:

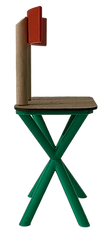

Make a chair that uses recycled material, flat-packs, and requires no tooling for the consumer to assemble

Tools:

-Illustrator

-Indesign

-Rhino

-BambuLab

-Keyshot

Timeline:

Fall 24'

10 weeks

Flat packable

Utilizes recycled material

Eliminate tooling in assembly

How might I design a chair that is sustainable and can be assembled by users of all abilities?

Form Evolution:

While sketching ideas and forms for a chair that could be assembled without tools, I was with a group of friends cooking dinner. During that I began to look at the same things and gestures that I'd seen 1000 times from a different perspective.

I noticed that when someone grabbed a set of chopsticks their hand became a natural stabilizing element

to the utensils, that to me, resembled chair legs. The chop sticks slid into the hand, and the hand acted

as a brace in the middle of them, creating tension and balance.

The hand was able to organize the loose chopsticks into a balanced, splayed structure.

I looked at my friends holding their chopsticks and instead of seeing a tool to eat,

I started to see a form that created tension, balance, and support all at once.

.png)

.png)

.png)

I thought to myself, how might I recreate this ideology into my design language.

Design Opportunity:

The number of chairs that offer tool-free, universally accessible assembly, ship flat for more sustainable transport, and use recycled materials is extremely small. Very few designs more than one of these goals, let alone all three.

This creates an opportunity to design a chair that unites all three objectives beautifully.

How can plastic support that much weight?

Traditional chair joints depend on glue, fasteners, and precision fit to hold components together. Although durable, these systems work against flat-pack design, often include sections that are permanent bonded and require tooling to assemble. This prevents ease of assembly, disassembly, and long-term part replacement.

Rather than relying on screws or permanent glue for the bulk of the chair, the twist joint uses interlocking geometry to hold the chair together. Parts slide into place and lock with a simple twist, creating a strong, secure connection without tools. This approach makes the chair intuitive to assemble, easy to take apart, well suited for flat-pack shipping, and affords to easily incorporate individual replacement parts if needed.

Why Choose aTwisting Joint?

I started with 1/8th scale chair studies, experimenting with different twists and curves to understand what felt creatively compelling while still looking visually structured and a user would view as safe to bare weight

After narrowing in on the overall form and leg structure, I developed larger 1/5th scale mockups to continue refining proportions and details.

I then created a mockup with similar color, feel, and materials as I would be making it in 1:1 scale to ensure I was liking the overall silhouette, balance, and structural rhythm.

This step in the process is about tiling out digital mockups and creating tangible 1:1 technical drawings.

This is the point that I take my 1:5 scale model and see how it looks in proportionally in space as a

full scale chair. This mock up was held together with tape and glue and was to bring perspective

to the chair in real time and space to see what alterations needed to be made stylistically.

Starting my first 1:1 prototype

1:5 scale...

...to 1:1 scale!

I utilized CNC machining to test tolerances and mill the seat and backrest, ensuring precise fit between the wood and plastic components.

To join the backrest to the chair structure, I machined a series of slots in the rear of the backrest using a drill press.

I tested both a round and a more squared seat at a larger scale, ensuring the components that the legs lock into were evenly spaced to support balanced load distribution.

I inserted the legs into the components beneath the seat, testing how increasing the diameter that the plastic components are laid out effected the varying height the joint rested at. This was a multifaceted consideration that required extensive testing and careful leveling.

Through repeated iteration, testing, component remodeling, and design reworking: I kept refining.

Reimagining sustainability,

comfort, and accessibility.

Twist.

Flat Pack:

By designing the chair to flat-pack, material use and shipping volume are significantly reduced, lowering transportation impact while making the chair easier to store, ship, and assemble. Twist compacts to a 24"x17"x6" box and Im confident with more time and adjustments, that box can be even smaller.

This is a fully realized physical prototype built to the exact dimensions shown above, with ample remaining room within the packaging.

Color, Material, Finish:

According to the United Nations, over 400 million metric tons of plastic are produced each year, with most never being recycled. With this reality, material choice becomes an environmental responsibility. Rather than always defaulting to black, Twist can utilize color as a sustainability strategy. Recycled plastics naturally vary in tone and texture. These expressive colors turn variability into a visual asset, encouraging emotional attachment, long-term use, and repair over disposal because no two chairs will be exactly alike.

cherry

blossom

midnight

ink

artic

breeze